$0.00

Meticulous Attention to The Finest Details has Countless Benefits

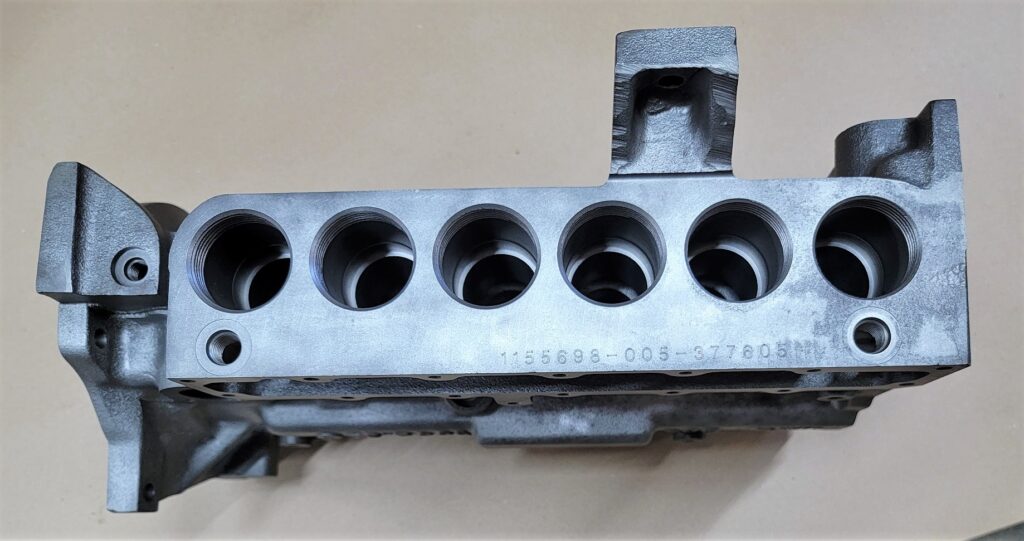

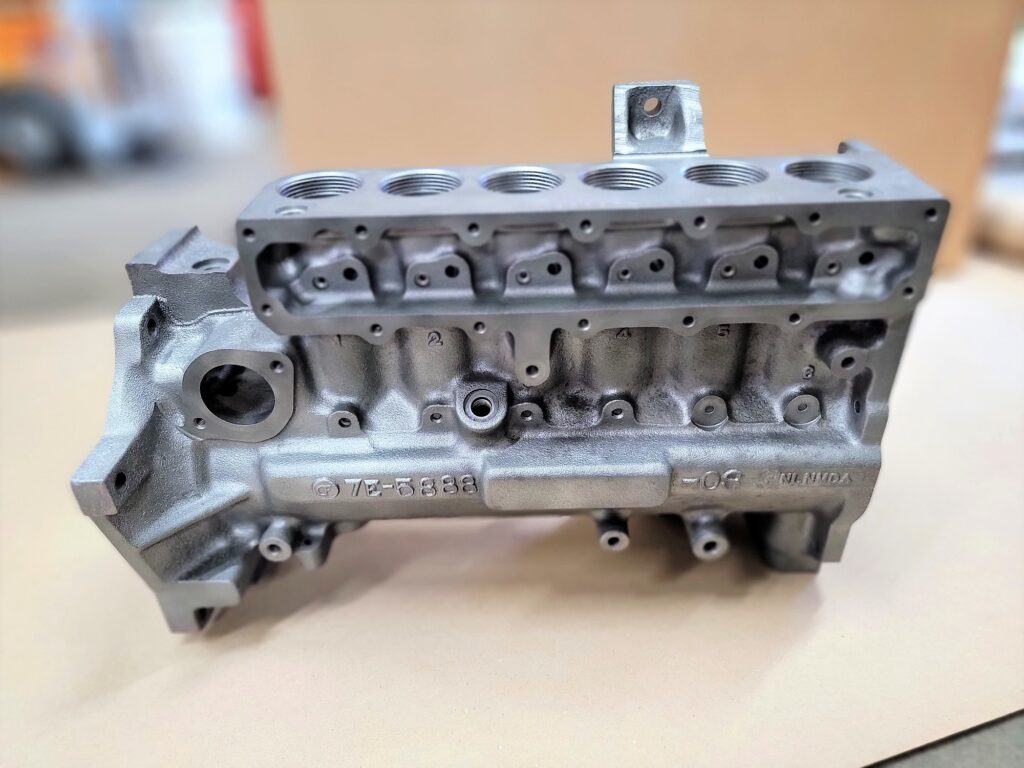

Is it brand new or three decades old? Well, when it’s tough for us to tell, we know the final inspection and rebuilding process is ready to start.

Few shops choose to invest the additional time and effort that we do when prepping all of the parts. For us, maximum quality and reliability is our only goal. Because of that, we don’t see the extra painstaking effort as an efficiency choice.

For example, prolonged hot-tanking and thorough bead blasting have two important results. The first is that even trace contaminates are fully eliminated. Over time, trace contaminates can eat away at seals and gaskets along with degrading lubricant’s on high-friction surfaces.

The second is that tiny cracks and dings can’t be seen unless the parts are back to like-new condition. And we all know that many tiny cracks don’t always stay tiny with temperature extremes and the repeated physical shocks and jolts heavy equipment is subject to.

But there’s also a psychological aspect. Intricate building processes always proceed at a far higher level of care when all of the parts in front of you are immaculate and like new. Because our parts are always immaculate, our work areas and tools tend to stay immaculate too.

If you find yourself imagining a group of skilled technicians in white lab coats working in a NASA clean-room, that’s probably going a little far. But we are a lot closer to that than the typical shop that does this important work.